I have always wanted to build a set of chairs from a single tree. I finally found the time to realize that dream when my departure from the established architectural firm I had founded in order to start a new one happened serendipitously to coincide with the moment the recession hit. During the lull before the business of architecture began to pick up again, I began to design and build what came to be called my Recession Chairs.

The process of making something from wood is an unpredictable journey, guided by materials, ability, and vision. These factors evolve and interact until, with time, thought, and a lot of trial and error, the task becomes clear.

For this project, I cut a large black walnut tree on our farm. I sawed most of the trunk in a conventional manner, producing wonderful wide planks and thick turning stock, but I also had in mind something a little different: where the primary branches connected to the trunk, instead of cutting them off, I saved those joints and sliced them laterally. The resulting curved grain suggested the design of the chairs. Wood has tremendous strength along the cellulose fibers that make up its grain. I wanted to take advantage of the natural strength of those curved pieces, as well as their voluptuous shape, to create arms and backs that would be thin and lightweight, gracefully flowing, and naturally ergonomic to accommodate the curves of the human back.

A chair is a difficult object to build because it demands more strength and comfort than other furniture. In addition, my design involved the use of compound curved pieces with complex grains. I am a proficient woodworker, having learned as a child from my father, later studying with master woodworkers in college, and - over the years - building everything from bowls to tables to houses. However, like most woodworkers, I had always focused on methods of joining straight-grained pieces of wood. Those standard joints would work for parts of the chairs, but not the curved arms and backs. I would have to expand my knowledge and abilities through research and experimentation. I began by exploring in books, museums, and antique shops to find the type of woodworking joints my design called for. I then experimented, building mockups, first just of the joints, then of the whole chair. The process of constructing prototypes, testing them, modifying the designs, and re-building, took months. Many chairs broke before I developed the design that married strength, comfort and beauty to my satisfaction. (One quick shout-out: I was fortunate to have readily available a human subject capable of performing brutally rigorous assessments of the chair’s strength… me.)

Each chair consisted of 21 handmade parts, which meant that the task of building ten chairs required identifying and organizing 210 pieces of black walnut with appropriate grain and dimensions, plus a few extras (for replacing casualties of large water buckets for the emu that Julie carried through the woodshop). I built the seats first, legs and struts second, and backs and arms third. The seats were made of four interlocking frame parts, with a floating solid panel in the center.

When the seats were complete, I proceeded with the legs and cross struts, which were time consuming. I had to turn forty identical legs on the lathe and then reinforce them with horizontal struts that were doweled to each leg.

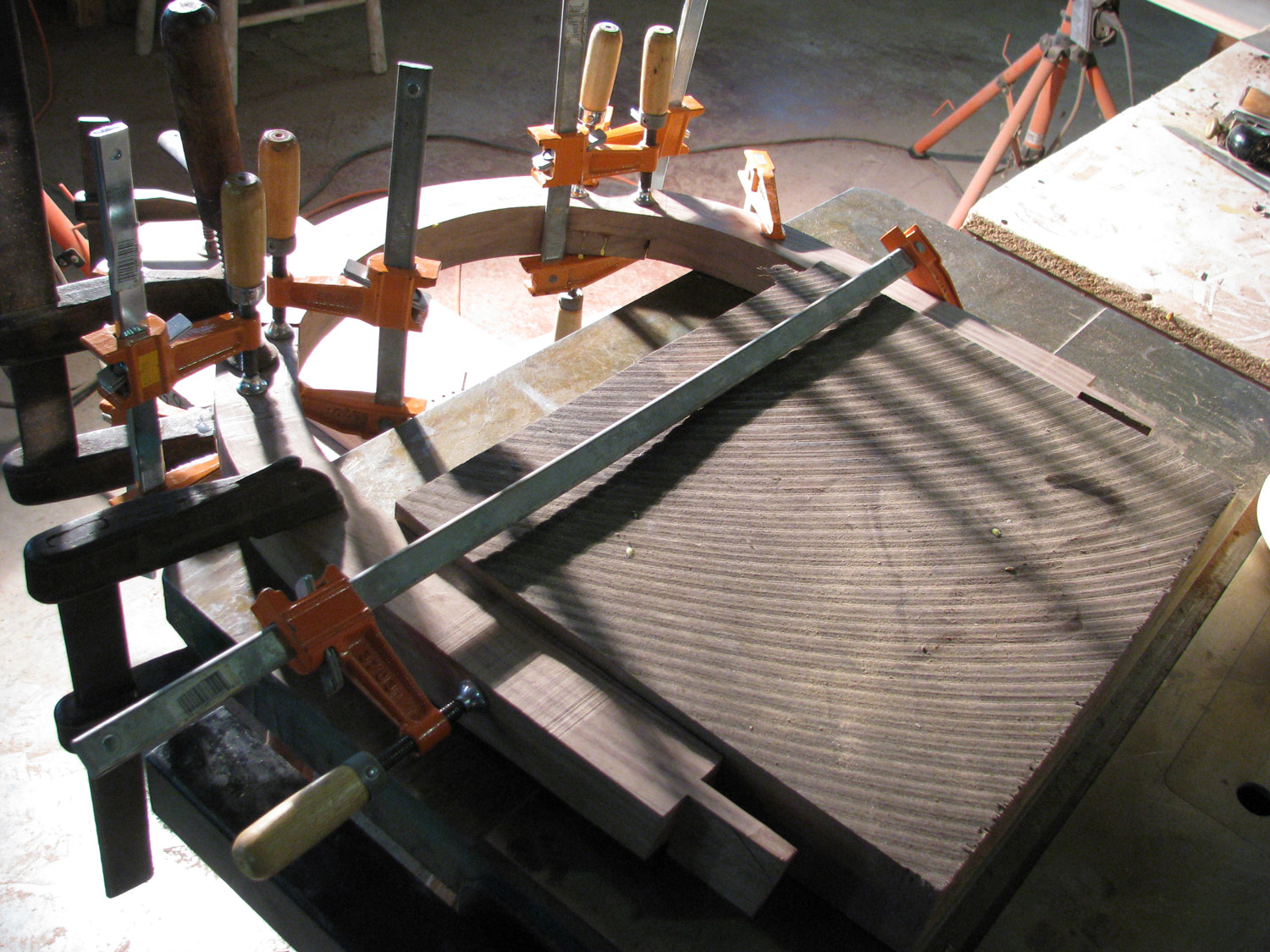

The most difficult task during the construction of the chairs was the arms and backs, which had to be carved by hand and fitted individually to the seats. There were five parts to the curved hoop that rose out of the seat in the front of the chair. Each part was radial in section as well as curved in plan. Fabricating each of these pieces required following the curved grain of the wood, which allowed very little room for error. The curve of the wood grain had to match the curve of the chair’s back and arms, which had to match the curve of a human body that would sit in the chair, if it were to be successful. Each piece needed to be carved with hand tools. The ten chairs are similar enough to one another that they look like a set, but different enough that I can tell them apart by touching them.

When the woodworking for the ten chairs was completed, the chairs were saturated with linseed oil that had a small amount of pine pitch and mineral spirits added as a coagulant. The wood was allowed to dry for one month, and then buffed smooth. A final surface of beeswax from our apiary will be applied just before we begin to use the chairs on Oak Hill Road.

I would never wish for a recession, but the Recession Chairs are my lemonade from that lemon.